Loading...

Motivations for Extended Producer Responsibility (EPR) practices include a mixture of economic, environmental, and social factors.

About the Author

Experienced Digital Marketer with a demonstrated history of working in the Internet industry. He likes to write about the latest technology trends, Skilled in Digital Marketing likes. Search Engine Optimization, SMO, SEM, PPC, Content Writing, and, Designing, etc.

Related articles

Environmental Compliance Updates Industries Must Know in 2026

2026-02-17

CPCB Mandates OCEMS Installation for Industries in NCR-Delhi

2026-01-28

Amendments in EPR Authorization for Electronic Waste

2025-11-07

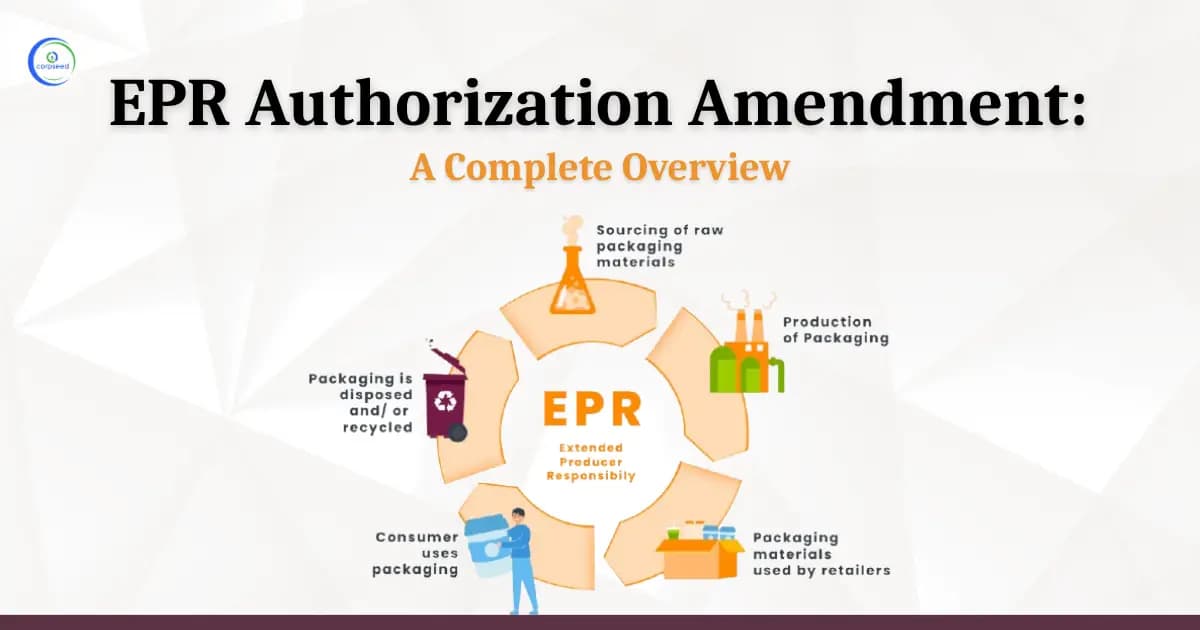

EPR Authorization Amendment: Step-by-Step Overview

2025-10-31

What is EPR Registration Certificate?

2025-08-22

.webp&w=1536&q=75)

How to Start a Biodegradable Packaging Business in India

2025-08-19